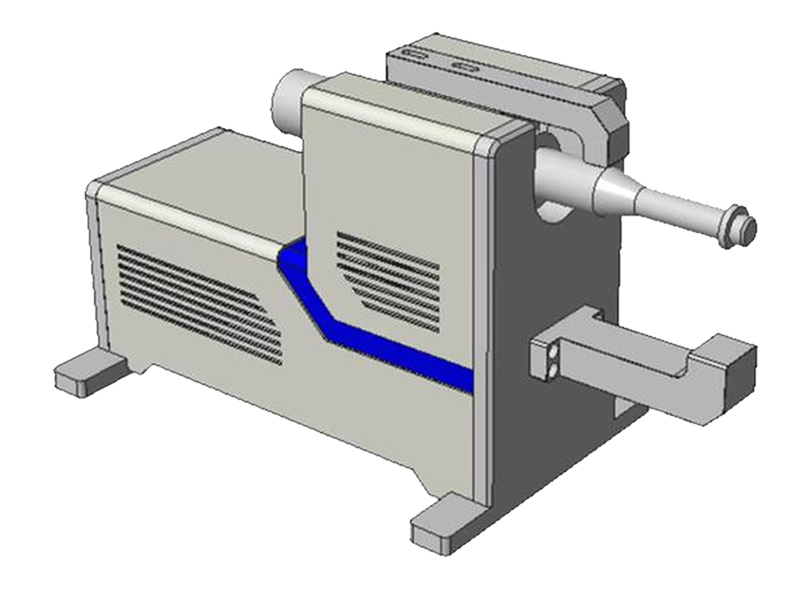

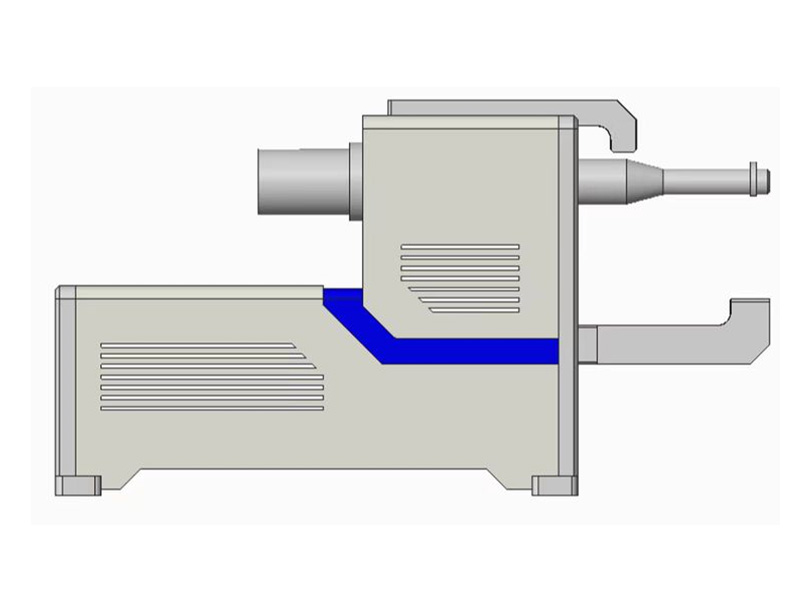

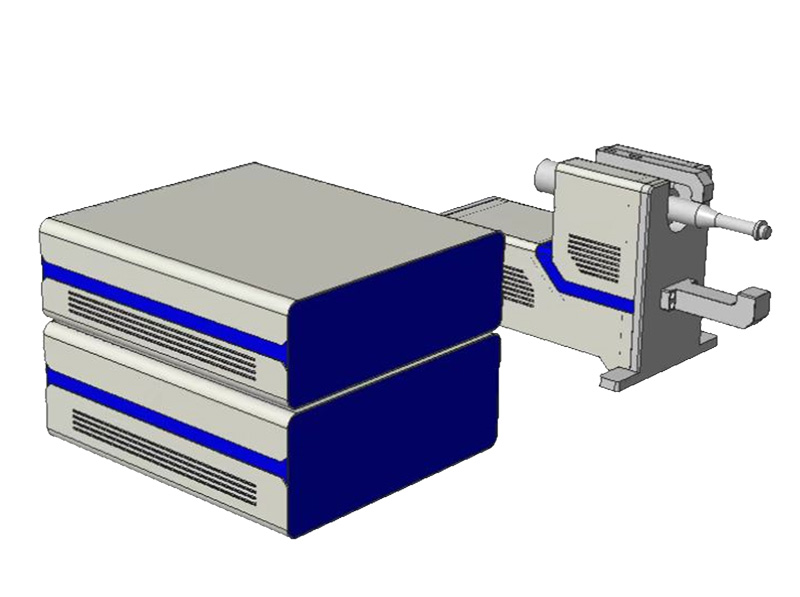

The design and manufacture of CGO-C28 ultrasonic welding system ensure a high degree of reliability and welding quality.

CGO is a leader in ultrasonic metal connection through our CGO product portfolio.

We have established cooperative relations with photovoltaic, medical, automotive, battery, refrigeration, electrical appliances and other industries.

Years of experience has provided us with a broad base of applied knowledge. Ultrasonic metal welding provides customers with perfect solutions and excellent performance.

Main features:

• Precision roller bearing slideways ensure smooth operation and high accuracy.

• Precise adjustment and accurate setting of upper and lower dead center.

• Dovetail installation allows quick replacement of fixtures.

• Quick installation of solid steel angle, lower mold cost, and replaceable end of titanium angle.

• Optional eddy current cooling, allowing high-speed operation without heat accumulation.

Advantages of CGO ultrasonic system:

|

process control |

Monitor ultrasonic welding by time, energy, power and height limits |

| Cost and environment savings | Eliminate consumables such as solder, flux, crimp connectors, and brazing materials |

| speed | Typical welding cycle is less than 0.5 seconds |

|

Low operation cost |

Less than 1/30 of resistance welding energy |

|

Tool life |

The precision machining multi blade cutter made of high-quality tool steel has long service life, simple setting and accurate welding precision |

| Insulating dispersion | In most cases, high-frequency scrubbing eliminates the need for magnetic wire components or stripped insulation |

|

Low operating temperature |

Minimal heat generation, so metal parts do not anneal and do not require cooling water |

| Automation potential |

Efficient size, minimal maintenance and directional flexibility make Changjiang ultrasonic equipment an ideal choice for automatic assembly |

| Frequency 20kHz | 20kHz、35kHz、40kHz |

| output power | 3.3 kW*, 4.0 kW, 5.5 kW |

|

Power Supply |

220VAC, 50/60 Hz, 30 Amp |

|

compressed air |

80 psi (5.5 bar) |